1. Highly Productive - increased profits!

UNO Finishing system is capable of High-speed production (510,000 notes/hour, 8F/NH) with not only specific face ups but also the most of the available face ups in actual production (between 32 face ups to 60 face ups). Here is a list of features that makes our system achive both high-speed production and producing good quality products.

"Super Fine Finishing"

ensured by “Shear cut” method at Trim section

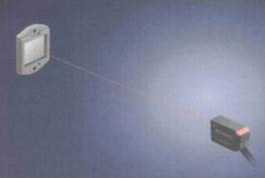

"Laser Beam sensor"

detecting cut – remainders at the bottom of Notes.

"Swing Cut Motion of Knives"

ensures, Low level Shock & NoiseIncorporated with newly adopted pneumatic Clutch & Brake,working, also, on THREAD & HOLOGRAM mixed "High grade Security Notes".

"Servo Drive Transfer"

Transportation at left hand/2nd(strip cutter)/ 3rd(edge trimmer) & 4th(finish trimmer) Trim sections are controlled by “High precision” Servo Motors in order to secure.

"Random Cut Function"

at Trim section No. 2 (strip trimmer) & No. 4 (finish trimmer) This ensures to maintain the high trim accuracy as compensating slight stretch on the surface of paper sheet, created by Intaglio print, affecting sensibly the trim position, by presetting data into Panel-display (Touch-panel). “Repeatability” that is very important to keep Trim Accuracy.

"Robotic Servo Controller"

at Trim section No.3 (edge trimmer) Being incorporated with the above 5 features, this Function can also Compensate slight stretch keeping always the high trim accuracy.

“STABILIZED PERFORMANCE”

Highly productive & efficient in high speed, regardless of face-up (between Minimum and maximum face-up).

2. Operator friendly, Manpower saving

UNO's Finishing system doesn't select the specific printing machine or the specific quality control machine (SNIM), so the customer can selects their prefered systems for the preprocessing and the postprocessing of our system. The system incorporates a lot of sophisticated functions, however the operation is kept simple so our system will be appreciated by both Manager and Operator.

"Touch-screen type Control Panel"

having many functions like a Memory-Card insert is available for Data-Filing on production history.

Delivery*

This is the final process at the DELIVERY Section Showing the precisely sequential number controlled, Buffered 1000 notes, as the final product.

*4F&8F-Link

"UNO FLAT BUFFER System"

*4F&8F-Link

Fully Automatic Robotic in-feed Device, as the in-feed to the Following Quality Control Machine.

*4F&8F-Link

3. Customer around the world!

Since the establishment back in 1929, UNO has been continuing manufacture HIGHLY PRODUCTIVE & HIGHLY EFFICIENT SYSTEMS to bring more profits to our customers around the world.